(Published on iVT International – March 2016, page 84)

Principle of operation

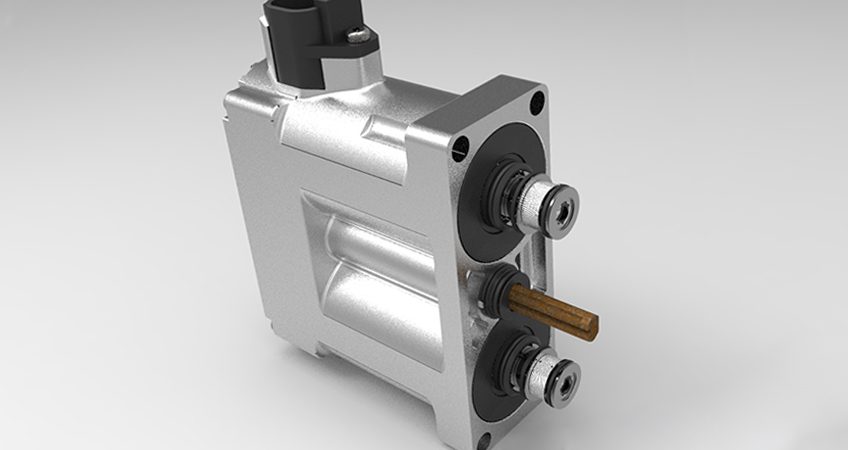

Tecnord’s MLT-FD5/D electrohydraulic proportional actuator has been designed to shift a directional control valve spool either directly (FL version) or by means of a servo piston that is mechanically connected to it (SP version). The internal closed-loop position control of the MLT-FD5/D makes the valve spool achieve the desired position with accuracy levels approaching the performance of a servo valve, by continuously comparing the setpoint of a remote control device (e.g. potentiometer, joystick, machine management system) with the feedback signal generated by a high-precision Hall-effect position transducer. Applications include the high-performance proportional control of stackable or monoblock directional control valves, as well as proportional control of variable displacement pumps and motors. Two Independent proportional valves provide a flow rate of 0.3 l/min, work pressure of 12-35 bar, and failsafe return to neutral in case of power loss. The Hall-effect contactless spool position sensor excellent linear control on 100% of spool travel; 8mm standard control stroke from each side of Neutral/13mm for Float position in one direction only; and prevents “cross-talking” between adjacentwork sections.

The built-in electronics feature an analod operating mode with +5V supply to external potentiometers or joystick controllers – with position feedback through analog voltage. In the other operating mode, the remote control setpoint is provided via CANbus according to ISO 11898 at 250Kb/s or 500Kb/s by means of standard SAE J1939 messages. Diagnostic messages are also available from the MLT-FD5 actuator.